Project Gallery

Featured Projects

Hawk Falls Bridge

Pennsylvania

I-64 Kanawha River Bridges

West Virginia

Nice-Middleton Bridge

Maryland-Virginia

Rappahannock River Bridges

Virginia

Scudder Falls Bridge

Pennsylvania - New Jersey

CSVT River Bridge

Pennsylvania

Governor Mario M Cuomo Bridge

New York

Kosciuszko Bridge

New York

Greenfield Bridge

Pennsylvania

Lewis and Clark Bridge

Indiana - Kentucky

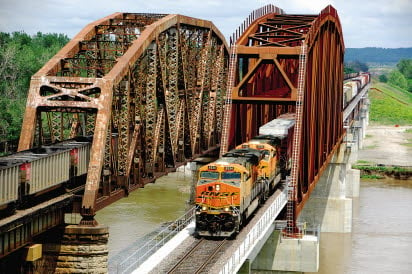

BNSF Plattsmouth Bridge

Nebraska - Iowa

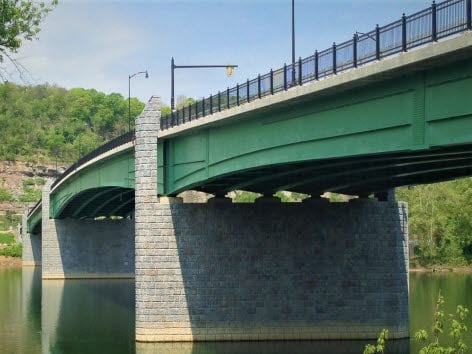

Jim Thorpe Memorial Bridge

Pennsylvania

Lake Champlain Bridge

New York - Vermont

Arthur Ravenel Jr. Bridge

South Carolina

Milton-Madison Bridge

Kentucky - Indiana

Woodrow Wilson Bridge

Virginia - Maryland

Douglass-Anthony Bridge

New York

I-95 / I-695 Interchange, Phase 1

Maryland

Route 22/322 Bridge at I-81

Pennsylvania

Manhattan West Crane Runway

New York

National Museum of Jewish American History

Pennsylvania

Questions about your project?

Do you have questions about best practices in steel bridge design for fabrication?

Need assistance with budget pricing, erecting, or shipping your structural steel?

Reach out to High Steel's experts - we look forward to helping you.